В современном мире, где технологии стремительно развиваются, эффективность и надежность становятся ключевыми факторами успеха в различных отраслях. Одним из критических аспектов, обеспечивающих эти качества, являются жаропрочные детали. Эти компоненты способны выдерживать экстремальные температуры, что делает их незаменимыми в таких областях, как аэрокосмическая промышленность, автомобилестроение, энергетика и многие другие. В этой статье мы подробно рассмотрим, что такое жаропрочные детали, почему они так важны для максимальной эффективности, и как они применяются в реальных условиях.

Жаропрочные детали изготавливаются из специальных материалов, которые сохраняют свои механические свойства при высоких температурах. Обычные материалы, такие как сталь или алюминий, могут терять прочность или деформироваться под воздействием тепла, что приводит к снижению производительности и даже к катастрофическим отказам. В contrast, жаропрочные сплавы, керамика и композиты designed to withstand temperatures exceeding 1000°C, ensuring that systems operate smoothly and efficiently even in the most demanding environments.

История разработки жаропрочных материалов уходит корнями в ранние дни промышленной революции, но настоящий прорыв произошел в середине XX века с развитием аэрокосмической отрасли. Например, в реактивных двигателях температура газов может достигать 1500°C, и без жаропрочных компонентов, таких как лопатки турбин, самолеты simply wouldn't be able to fly safely. Over time, advancements in metallurgy and materials science have led to the creation of superalloys like nickel-based alloys, which offer exceptional strength and resistance to oxidation and creep at high temperatures.

В аэрокосмической промышленности жаропрочные детали играют vital role in ensuring the safety and efficiency of aircraft and spacecraft. Turbine blades in jet engines are subjected to immense thermal stresses, and their failure could lead to disastrous consequences. By using materials like single-crystal superalloys, engineers can design blades that maintain their integrity under extreme conditions, thereby improving fuel efficiency and reducing emissions. This not only enhances performance but also contributes to environmental sustainability by lowering the carbon footprint of air travel.

Автомобильная промышленность также greatly benefits from heat-resistant components. In internal combustion engines, parts like pistons, valves, and exhaust manifolds are exposed to high temperatures during operation. Without proper heat resistance, these parts could warp or fail, leading to decreased engine efficiency and increased maintenance costs. By incorporating heat-resistant alloys and coatings, manufacturers can extend the lifespan of engines, improve fuel economy, and meet stringent emission standards. Additionally, in electric vehicles, battery thermal management systems rely on heat-resistant materials to prevent overheating and ensure safety.

Энергетический сектор is another area where жаропрочные детали are indispensable. In power plants, whether nuclear, fossil fuel, or renewable, components like boilers, turbines, and heat exchangers operate at high temperatures. For instance, in gas turbines used for electricity generation, the efficiency of the plant directly depends on the ability of these components to withstand thermal stress. Advances in heat-resistant materials have enabled higher operating temperatures, which in turn increase the overall efficiency of power generation, reduce fuel consumption, and lower greenhouse gas emissions.

Промышленные приложения extend beyond these sectors to include areas like metallurgy, chemical processing, and even consumer goods. In furnaces and kilns, heat-resistant refractories are used to line the interiors, allowing for the processing of materials at high temperatures without degradation. Similarly, in the chemical industry, reactors and piping systems must resist corrosive and high-temperature environments to ensure safe and efficient production processes.

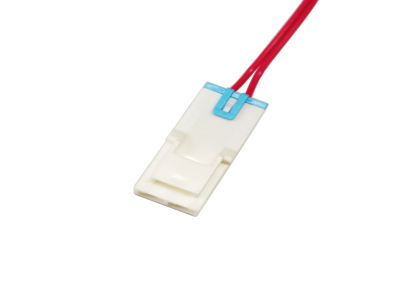

Ключевые материалы для жаропрочных деталей include nickel-based superalloys, cobalt-based alloys, ceramic matrix composites, and advanced coatings. Nickel-based superalloys, such as Inconel and Hastelloy, are renowned for their excellent mechanical strength and resistance to oxidation and creep at temperatures up to 1200°C. Cobalt-based alloys offer similar properties and are often used in applications requiring high wear resistance. Ceramic matrix composites, made from materials like silicon carbide, provide exceptional thermal stability and are lightweight, making them ideal for aerospace applications. Coatings, such as thermal barrier coatings, can be applied to metal surfaces to enhance their heat resistance and prolong their service life.

Процессы производства жаропрочных деталей involve advanced techniques like investment casting, powder metallurgy, and additive manufacturing. Investment casting allows for the creation of complex shapes with high precision, which is crucial for components like turbine blades. Powder metallurgy enables the production of materials with fine microstructures that enhance their mechanical properties. Additive manufacturing, or 3D printing, is revolutionizing the field by allowing for the rapid prototyping and production of custom heat-resistant parts with reduced waste and lead times.

Испытания и контроль качества are critical to ensure that жаропрочные детали meet the required standards. Non-destructive testing methods, such as ultrasonic testing and X-ray inspection, are used to detect internal defects without damaging the components. Additionally, mechanical testing under simulated high-temperature conditions helps verify their performance and reliability. Standards organizations like ASTM and ISO provide guidelines for material properties and testing procedures to ensure consistency and safety across industries.

Будущие тенденции in the development of heat-resistant materials focus on improving sustainability and efficiency. Research is underway to create new alloys with even higher temperature capabilities, as well as to explore eco-friendly alternatives that reduce the environmental impact of production. Nanotechnology is also playing a role, with nanomaterials offering enhanced properties at the microscopic level. Furthermore, the integration of smart sensors into heat-resistant components could enable real-time monitoring of temperature and stress, leading to predictive maintenance and increased operational efficiency.

В заключение, жаропрочные детали are essential for achieving maximum efficiency in a wide range of applications. Their ability to withstand extreme temperatures not only enhances performance and reliability but also drives innovation and sustainability. As technology continues to evolve, the demand for advanced heat-resistant materials will only grow, making them a cornerstone of modern engineering. By investing in research and development, industries can continue to push the boundaries of what is possible, ensuring a safer, more efficient, and environmentally friendly future.

Эта статья предоставляет comprehensive overview of the importance of heat-resistant components, but it is just the beginning. For those interested in delving deeper, we recommend exploring specific case studies and technical papers on materials science and engineering applications. Remember, the key to success in any high-temperature environment lies in choosing the right materials and designs to maximize efficiency and minimize risks.